Overview

Marine-grade fixes for critical infrastructure

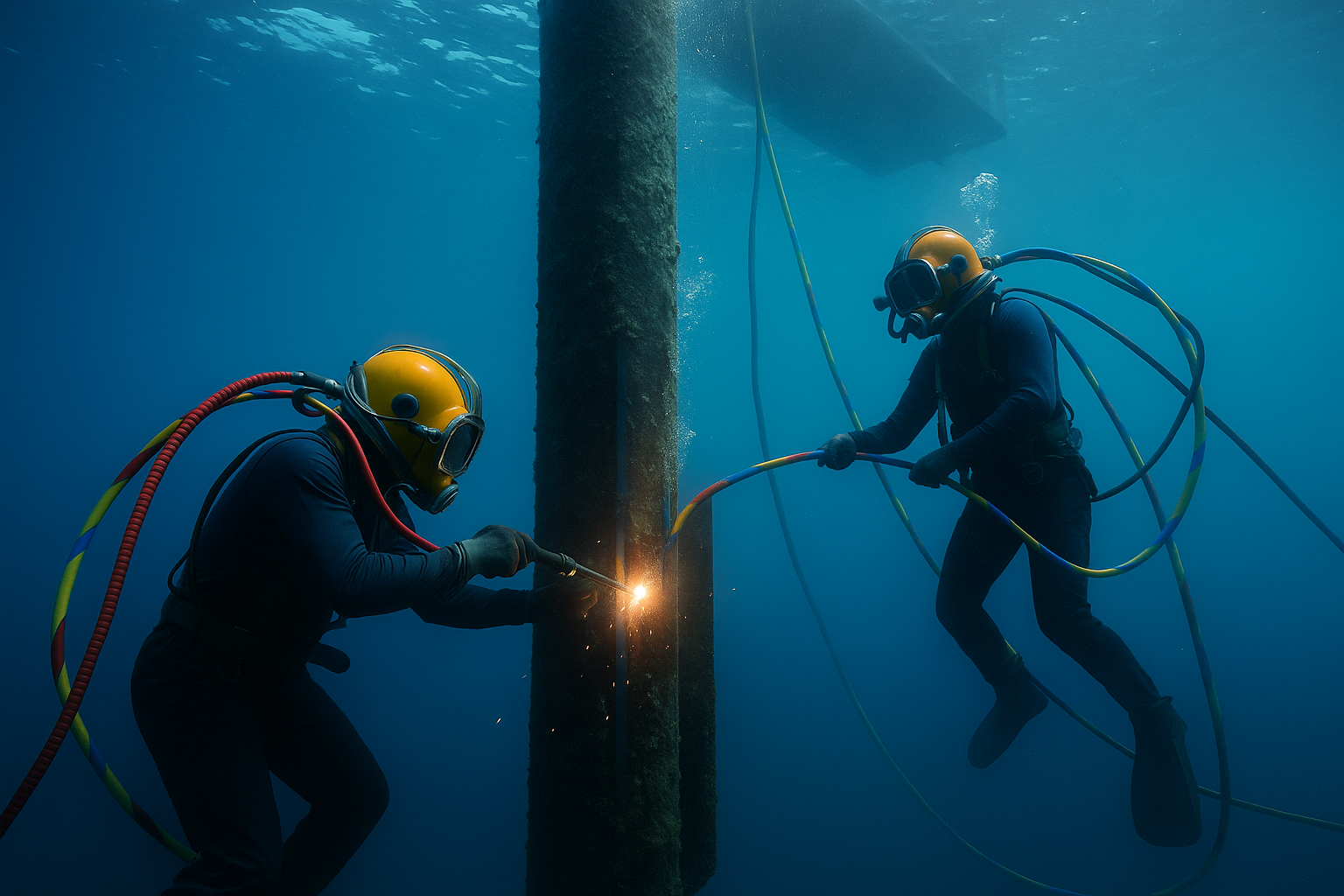

From ports and intakes to river crossings and outfalls, our dive teams execute wet welding and mechanical repairs that restore integrity fast—without full dewatering or shutdowns where safe and permitted.

- Wet SMAW/GMAW in accordance with AWS D3.6M (Class per project)

- Splash-zone structural steel, risers, guides, and ladders

- Mechanical seals, flanges, clamps, and spool piece installs

- Intake screens, anode systems, and scour protection