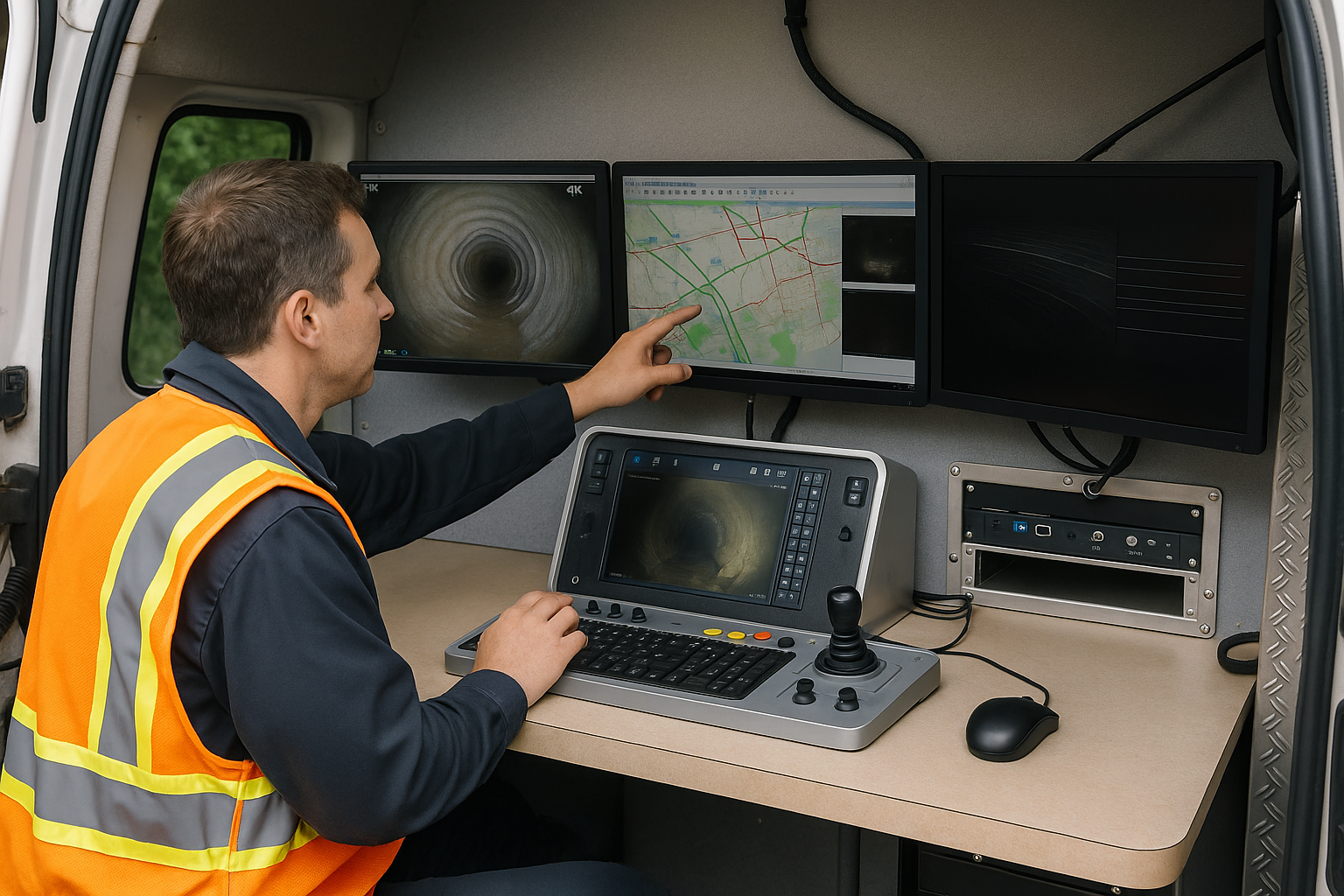

See more. Decide faster.

Our inspection teams capture high-fidelity video, code defects to NASSCO standards, and run leak checks so owners can prioritize repairs with confidence. Deliverables slot directly into your CMMS and GIS.

- 4K robotic crawlers with pan/tilt/zoom heads

- NASSCO PACP/MACP/LACP coding & scoring

- Acoustic correlation & pressure tests for leak pinpointing

- GIS shapefiles + PDF reports + raw video archives