Extend service life. Minimize disruption.

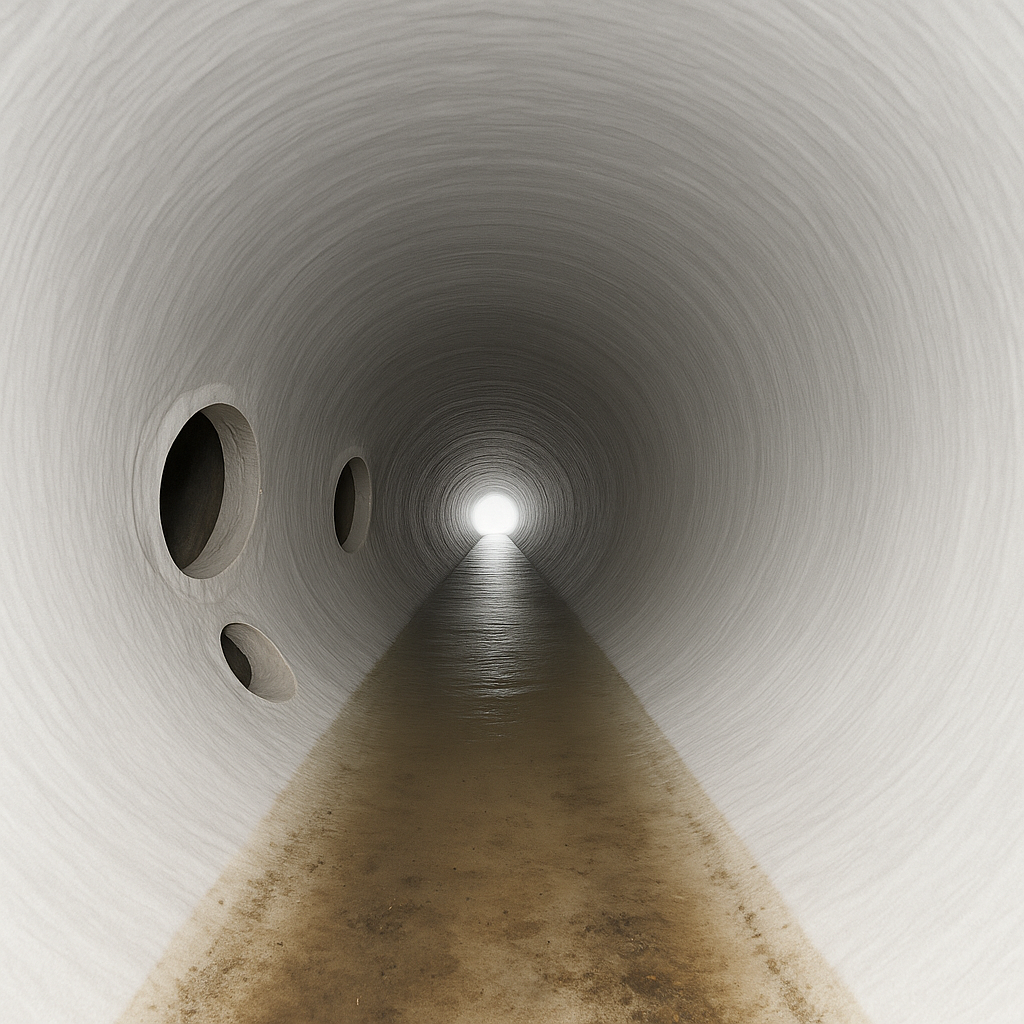

We install cured-in-place liners and sectional repairs to address infiltration, corrosion, and structural defects—without open-cut. Our crews manage bypass, reinstatements, testing, and handover so assets return to service quickly.

- Full-length CIPP liners and sectional point repairs

- Hot water, steam, or UV cure per project need

- Service reinstatement with robotic cutters

- Pressure/leak testing & full close-out documentation